YEAHUI ELECTRONIC LIMITED Yeahui Cable, connector to the world!

Home / blog

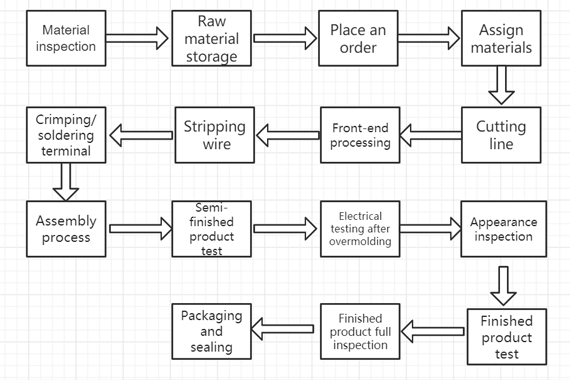

Different wiring harness factories may have different process names, but they will not deviate from the following main process modes. Below is YeaHui's wiring harness processing.

1. Material inspection: check the quantity and whether there is any damage and test whether all incoming materials required for the wiring harness meet the ROHS standard.

2. Raw material storage: after passing the material inspection, it will be stored in the warehouse and registered in the system.

3. Place an order: place an order to the warehouse to let the officer know.

4. Assign materials: the warehouse officer assign the materials according to the order.

5. Cutting wire: Cut the wire to the required length and strip the insulation of the wire length at the joint as required.

6. Front-end processing: Labeling, put on shrink tube and etc...

7. Stripping wire: we need do many process, like Stripping, Trimming Cotton and Aluminum Foil, Trimming Core and Stripping Coring.

8. Crimping/Soldering terminal: Use a terminal machine to weld the conductor joint, or soldering terminals, and ensure that the terminal is not deformed.

9. Assembly process: assemble the connectors to the wire.

10. Semi-finished product test: Use the electrical testing machine to test the performance of the wiring harness to ensure the wiring harness does not appear short circuit, open circuit, poor contact and etc.

11. Internal and external overmolding

11. Electrical testing after overmolding: test the performance of the cable assemblies.

12. Appearance inspection: Repair the bad edge, check whether the plug has damaged rubber core, blocked hole, shrinkage, lack of material, flow pattern, damaged wire, etc.

13. Finished product test: test the performance of the wiring harness to ensure the wiring harness is working.

14. Finished product full inspection: Check dimensions and specifications are consistent with the drawings.

15. Packaging and sealing: Arrange the cables neatly and put them in the carton

Above is the Wire harness processing in YeaHui factory, we have a complete quality control system along the processing, each cable will be 100% full inspection before shipment. Reliable Quality and customer’s satisfaction is always our high priority. Looking for a customized wire harness manufacturer? Contact the YeaHui team now!