YEAHUI ELECTRONIC LIMITED Yeahui Cable, connector to the world!

Home / blog

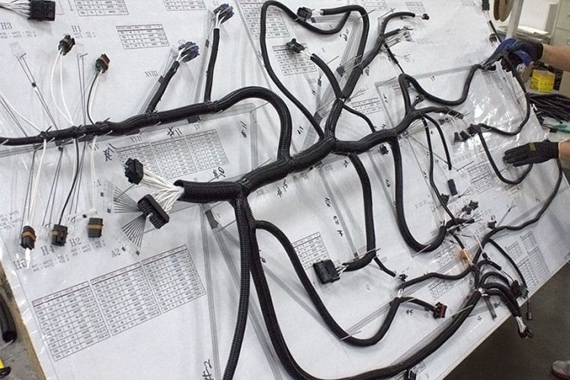

The wiring harness is made of many components. After the contact terminal is crimped with the wire and cable, the outside is molded with an insulator or a metal shell, etc., and bundled with a wire harness to form a component that connects the circuit. If the wiring harness is broken, the signal will be inaccurate, which will cause the vehicle to fail to start, and may also cause a fire; the wiring harness is the main body of the car circuit network.

Some of the causes of car wiring harness breaks:

1. Internal reasons:

a. The vehicle breaks during operation due to the too-short design of the branch line distributed by the main wiring harness of the vehicle;

b. Because the manufacturer did not implement the manufacturing standard when designing the wiring harness, it did not meet the standard, and the manufacturing was not standardized;

c. The wire harness is too tight when the assembly line is assembling the wire harness, resulting in breakage.

2. External reasons:

a. Wire harness breakage caused by wiring harness modification;

b. Wire harness breakage caused by mouse gnawing;

c. The wire harness is broken due to the scratching of the wire harness;

The way to repair a damaged wiring harness:

a. Firstly, remove the burnt insulation wrapping layer of the wire harness, cut off both ends of the burnt wire, reconnect the burnt wire with wires of the same specification and length, and wrap each joint with insulating tape.

b. When wiring, divide the two ends of the connection wire into two halves and twist them together separately, then twist the two twisted wires together again, bend them to be parallel to the wire and close to the wire, and wrap them with insulating tape.

c. If the wire harness is completely broken, it can be connected with a short wire. When connecting, the joints of the wires should be staggered from each other, and each joint should be wrapped with insulating tape, and finally, the connected wires should be wrapped with insulating tape.

YeaHui has 14 years of experience in producing wire harnesses with TUV ISO9001 certified. We specialize in this field, so if you have any requests for the wire harness, please feel free to contact us at any time!